Advanced Manufacturing

Overview

Advanced manufacturing plays a major role in the economy, at the national, state, and local level. According to the Brookings Institute, the nation’s 50 advanced industries employed 12.3 million U.S. workers in 2013, about 9 percent of total U.S. employment.

Universities have a unique role to play in the advanced manufacturing sector. In addition to contributing to the professional workforce, universities foster an environment of innovation. Whether it is the need for a new technology or a new way of looking at a process, the University of Mississippi’s talent and innovation in materials science, engineering, physics, and computer science can help.

Improving and Expanding Drug Delivery Systems:

The Pii Center for Pharmaceutical Technology conducts interdisciplinary drug/polymer research that provides end-stage pharmaceutical products directed at therapeutic conditions, vaccines, antidotes and wound care. Utilizing cutting edge thermal processing, the Pii Center collaborates with private industry, government and academia to develop new, improved and expanded drug delivery systems. A hands-on course in Tablet Technology focused on advanced pharmaceutical manufacturing is hosted by the Center with the assistance of outside experts from 18 companies.

Preparing Students for Manufacturing Careers:

The Center for Manufacturing Excellence (CME) partners with the Schools of Accountancy, Business Administration, and Engineering to offer a unique undergraduate degree for careers in manufacturing. Students gain the professional skills involved in successful manufacturing along with an understanding of accounting, communication, human resources, leadership, management, and marketing. The CME is closely tied to the manufacturing industry through its advisory board including executives from Toyota and GE Aviation. Along with extension and co-op programs, CME has extensive facilities including a 47,000-square-foot building with state-of-the-art classrooms, a 12,000-square-foot factory, assembly and finishing areas, and a robotics laboratory.

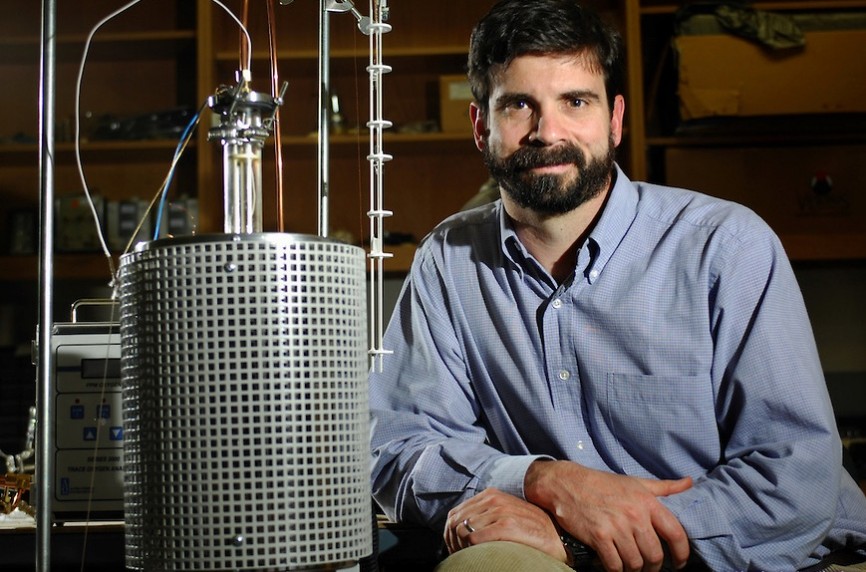

Top Talent in the Acoustics Arena Contributing to Collaborative Approach:

Established in 1986 by Congressional Act, the National Center for Physical Acoustics specializes in using acoustics to characterize the mechanical properties of novel materials at elevated temperatures, including thermoelectric materials, layered ceramics, composites, metallic hydrides, and soft structured materials like visco-elastic fluids and polymeric fluids that are common in a wide variety of industrial processes. NCPA also has expertise in sensors and methodology for structural health monitoring in extreme work environments such as air frames, jet engines, natural gas turbines, and nuclear reactor cores. NCPA partners with local Mississippi companies such as Radiance Technologies, Miltec, as well as national and international companies like Toyota, SAIC and others.

Responding to Industry Needs:

In response to an influx of Japanese companies locating in North Mississippi, the University of Mississippi established the North Mississippi Japanese Supplementary School (NMJSS) to help Japanese families and students settle in the area and to maintain their education and culture. NMJSS enables school-age children to keep up with their peers in Japan and to help them integrate smoothly into Japanese school life when they return to Japan.

Nationally Recognized Program in Pultrusion Research:

The Composite Materials Research Group emphasizes an interdisciplinary research approach to optimization of manufacturing process parameters, development of natural fiber reinforcements for the pultrusion of composites, development of new resins for pultrusion, effects of fillers and other additives on the processing and properties of pultruded composites, high frequency electromagnetic (EM) characterization of materials, and computational modeling of the pultrusion resin injection process. CMRG works with the National Science Foundation, the U.S. Air Force, Martin Marietta, NASA, U.S. Department of Agriculture, the Electric Power Research Institute, and numerous companies in the composite industry.